PIPE RELINING

Relining - Stronger Pipes For Longer

The major issue with blocked and damaged pipes is how complicated it can be to reach them, especially if they are far underground or under a building. In the past, we would need to dig the area and replace the entire pipe. Now, Reline-A-Pipe offers trenchless pipe relining to fix issues with drainage systems without the need for digging and destruction.

We use a range of technologies to remove blockages of varying difficulties, such as debris, grease, oil, mortar and tree roots. By using our extensive range of relining options, we can reline any section of a broken pipe without needing to replace the entire structure.

Faster Repair Time

Pipe Relining can take much less time to carry out the pipe repair, rather than a traditional dig-up.

More Cost Effective Solution

With a 50 Year Guarantee, you will spend less money on repair over to life of your pipes.

Less Mess To Deal With

There is no need to dig up your home or any structures to repair pipes fit for relining, which means minimal mess and disruption.

What is Pipe Relining?

Pipe relining is a modern, efficient method of repairing damaged or deteriorated pipelines without the need for extensive excavation. This technique restores the structural integrity and functionality of existing pipes, minimising disruption to the surrounding environment.

The process involves inserting a liner coated with a resin into the damaged pipe, which is then inflated and allowed to cure, forming a new, durable pipe within the old one. This method is particularly advantageous because it minimises disruption to the surrounding area, reduces labor and restoration costs, and often speeds up the repair process. Pipe relining is commonly used for various types of pipes, including those made of clay, PVC, and cast iron, making it an effective solution for a multitude of plumbing issues such as leaks, cracks, and blockages.

The Process of Pipe Relining

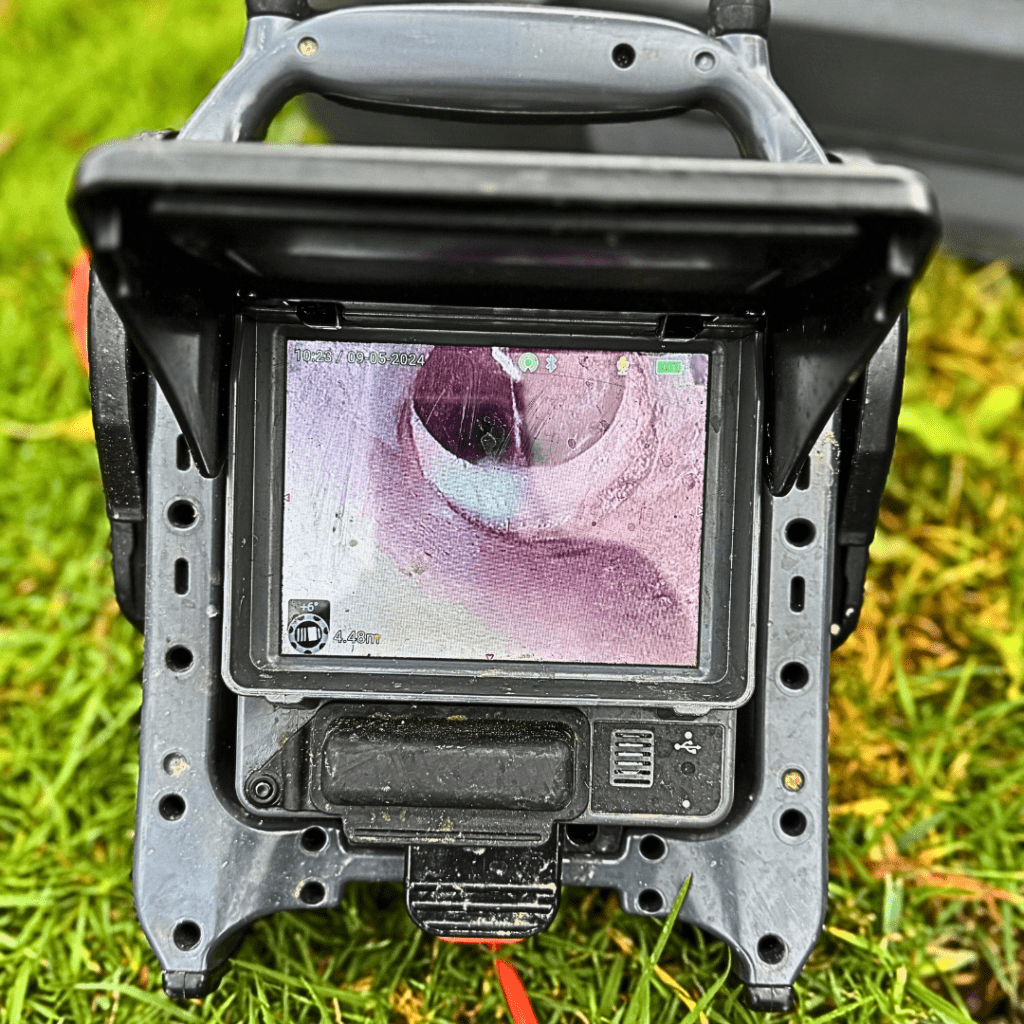

- Assessment and Inspection: The process begins with a thorough inspection of the pipes using advanced technologies such as video camera inspection. This helps identify the extent of damage, blockages, or leaks in the plumbing system.

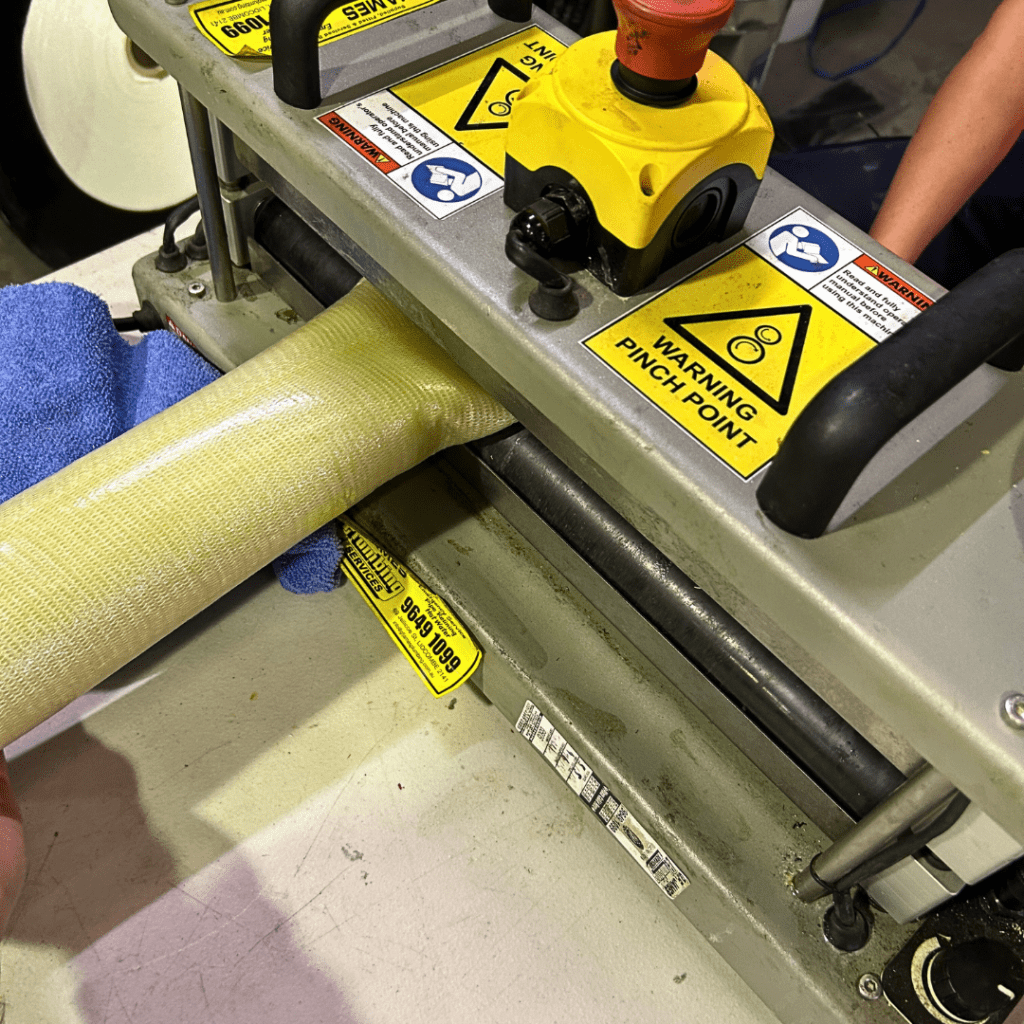

- Cleaning the Pipes: Once the assessment is complete, the pipes are cleaned using high-pressure water jets or mechanical methods to remove any debris, buildup, or obstructions. This step is crucial to ensure proper adhesion of the new lining material.

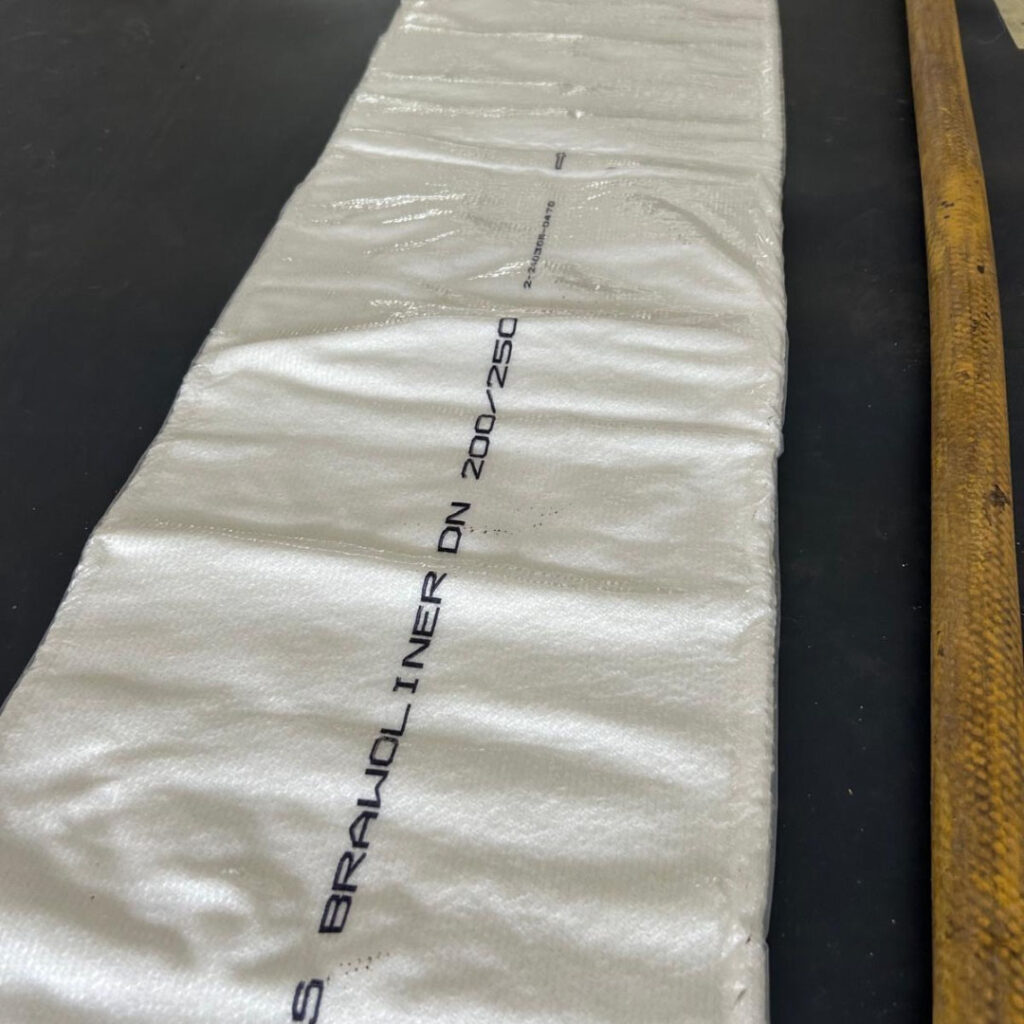

- Lining Material Preparation: A flexible liner, usually made of felt or fiberglass, is coated with a special resin. This resin is designed to harden and bond to the interior of the existing pipe once it is introduced.

- Insertion of the Liner: The prepared liner is then inserted into the damaged pipe. Depending on the type of relining method used, it can either be pulled into place or inflated to fit snugly against the walls of the existing pipe.

- Curing Process: After insertion, the resin is cured to harden it, effectively creating a new pipe within the old one. This curing can be achieved through various methods, including heat, UV light, or ambient conditions, depending on the liner material used.

- Final Inspection and Testing: Once the resin has cured, a final inspection is conducted to ensure that the relining was successful and that no leaks remain. The water flow is tested to confirm that the repair has restored the pipe’s functionality.

- Durability and Longevity: The new pipe lining is designed to be durable and resistant to corrosion, root intrusion, and other common issues that can affect traditional pipes. This longevity often makes it a cost-effective solution in the long run since it prolongs the life of existing plumbing systems.

- Environmentally Friendly: Pipe relining is a trenchless technology, meaning it requires minimal excavation and disruption to landscaping, driveways, or structures. This makes it an environmentally friendly option compared to traditional pipe replacement methods.

Pipe relining offers an effective solution for repairing pipes without the need to dig them up, saving both time and money while ensuring a reliable plumbing system in the long term.

Blueline technology has been specially formatted as the world’s most versatile epoxy pipe lining system – capable of rendering pipes from 40 to 1000mm better than new. This is the key-hole surgery of plumbing, removing obstructions with high-pressure water jets and completely restoring the structural integrity of the pipe without the need for digging.

Redline Pipe Repair

The redline solution from Reline-A-Pipe will safely and conveniently restructure broken or cracked pipes in residential, commercial and industrial settings. Redline is 100% safe for drinking water pipes, and air/gas lines. This technology causes minimal disruption and can completely eliminate leaks in pipes between 12mm and 300mm.

Greenline is our specialist technology, using epoxy resins to solve problems with water mains in diameters of 40mm to 600mm. This includes trenchless repairs for water mains that are hidden beneath tonnes of concrete and road. Using Greenline technology, we can offer structural repairs even when there is no existing pipe.

Inversion lining allows us to reline pipes in one continuous length of up to 50m, making this a great system for pit-to-pit sewer and stormwater drain lines. This technology doesn’t involve digging or damaging floors and the surrounding environment. Inversion is cost-effective, convenient and fast.

To discover which one of our pipe relining technologies is right for your home, business or industrial site, contact Reline-A-Pipe. We’ll organise a time to conduct a CCTV inspection of your pipes and make recommendations based on your needs. Call us on (02) 9649 398 or contact us online for assistance.

LATEST FROM OUR BLOG

3 Easy Ways to Unblock Drains Outside

How to Unblock a Bath Drain

Signs You Have Tree Roots In Your Drains

Pipe Relining Cost

Pipe Patching VS Pipe Relining

The Advantages of Pipe Relining Sydney

Relining Electrical Conduit – Can it be done?

Commercial Pipe Relining Services in Sydney

Pipe Relining Sydney

CLIENT TESTIMONIALS

WHAT OUR CUSTOMERS HAVE TO SAY ABOUT OUR SERVICES